HomeHolographic Stamping Foils

Holographic Hot Stamping Foils to Protect & Enhance Products

To improve security and authentication, holographic hot stamping foils from Holoseal can be applied/transferred to priceless documents, product labels, Pharma labels, textile labels, automobile labels, Electronic Labels, MRP Labels, Product Information Labels, Food Labels and packaging cartons. The production line already in place can easily be combined with the new process. So it becomes easy for manufacturers, converters & brand owner to use this process.

Holographic images are transferred via a heat (hot stamping process) on paper, film, clothing, and a variety of other surfaces for both decoration and authentication.

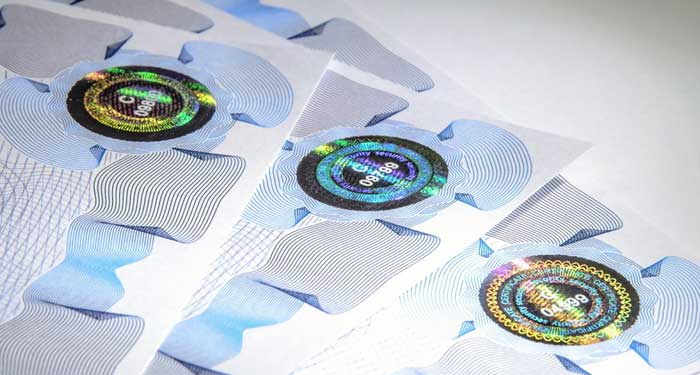

Customized design Stamping Foils supplied in roll form and embedded with holographic high security features, to protect your valuable documents and products from Duplication, Tampering & from Forgery. Many brand owners and products manufacturers in India and across the world use this Holographic Hot Stamping Foils to protect their brands.

For branding, holographic images can be transferred to pharmaceutical labels, cartons, tickets, coupons and other surfaces.

Running or Continuous Design Holographic Hot Stamping Foils

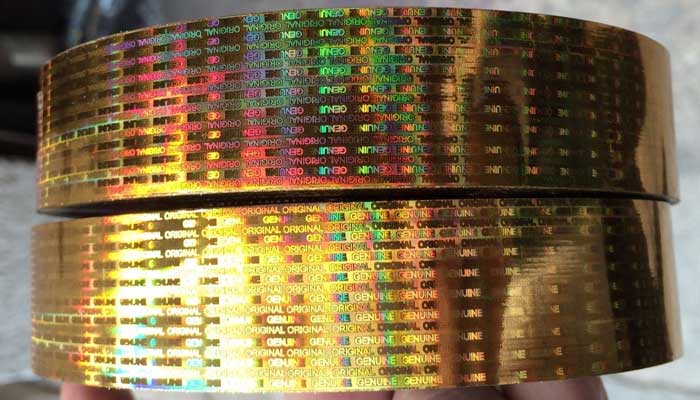

Holographic hot stamping foils are applied to various products, documents, and packaging materials through a heat transfer process known as hot stamping. This technique embeds striking holographic images, logos, or patterns—such as “Authentic,” “Genuine,” and “Original”—directly onto surfaces, enhancing both security and brand authenticity. Widely used across industries like banking, pharmaceuticals, food and beverage, tobacco, and wine and spirits, these foils provide a robust defense against counterfeiting and tampering.

Hot stamping foils create continuous holographic designs, offering a seamless, eye-catching effect that boosts product appeal. Additionally, they serve critical security roles in high-value applications including checks, stamp papers, currency notes, and other protected documents, where preventing forgery is paramount. Their versatility extends to product labels, cartons, and tickets, where protecting brand integrity is essential.

The process is compatible with existing production lines, making it easy for manufacturers, converters, and brand owners to integrate holographic hot stamping foils into their packaging or document authentication procedures. Overall, holographic hot stamping foils combine visual impact with advanced security features, making them an indispensable tool for protecting brand reputation and ensuring customer trust.

Holographic Hot Foils with Eye Mark for Precise Stamping

Registered holographic hot stamping foils are equipped with precise eye marks, enabling machines to accurately detect and stamp the exact holographic image placement on every label, card, or product. This registration ensures consistency and precision, which is critical in high-security applications where uniformity is paramount. Classic examples of registered holographic foils with eye marks can be seen on credit cards such as RuPay, Mastercard, and Visa, where each card features an identical, perfectly aligned hologram for secure brand authentication. These eye mark-enabled foils not only enhance security but also improve production efficiency by minimizing errors in foil placement.

Holographic Hot Stamping Foils Applications

Holographic hot stamping foil has several uses in a variety of sectors. Here are some examples of its applications: Product packaging, brand protection, government documents, banking and finance, event tickets, and luxury goods, among other things. Overall, holographic hot stamping foil is a flexible security feature that may be employed in a variety of sectors and applications. Because of its potential to combat counterfeiting, safeguard brand reputation, and improve product look, it is a must-have tool for many firms.

Holographic Hot Stamping Foils for Plain Paper Labels

Plain paper labels can be transformed into visually stunning designs using holographic hot stamping foils. The heat transfer method ensures the foils adhere perfectly, delivering vibrant, multidimensional effects. These foils not only enhance the aesthetic appeal but also provide added security, making the labels challenging to replicate.

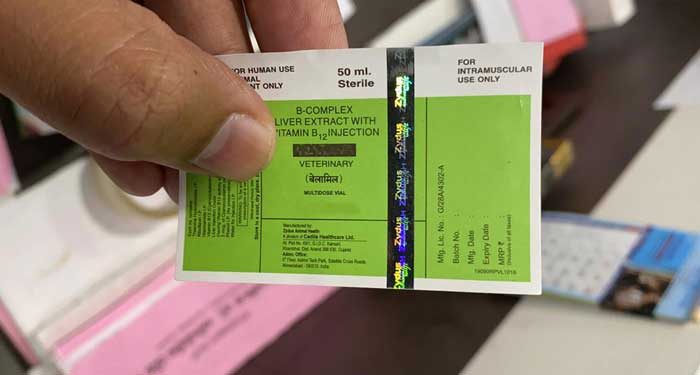

Holographic Hot Stamping Foils for Pharma Labels

Holographic hot stamping foils boost the appearance of pharmaceutical labels by combining aesthetic appeal with enhanced security. These foils are applied using a heat transfer process, resulting in striking, multi-dimensional effects that draw attention. The intricate designs are challenging to replicate, helping to prevent counterfeiting and ensuring product authenticity. Perfect for the pharmaceutical industry, these foils not only improve the look of packaging but also add a crucial layer of protection for brands and consumers.

Holographic Hot Stamping Foils for Automobile Labels

Holographic hot stamping foils are a smart choice for automobile labels, combining style and security. These foils enhance label designs with striking holographic effects, making brand logos and information highly visible and appealing. Beyond aesthetics, they add a layer of protection against counterfeiting, ensuring the authenticity of vehicle components. Whether used for branding or compliance labels, holographic hot stamping foils offer a blend of sophistication and reliability for the automobile industry.

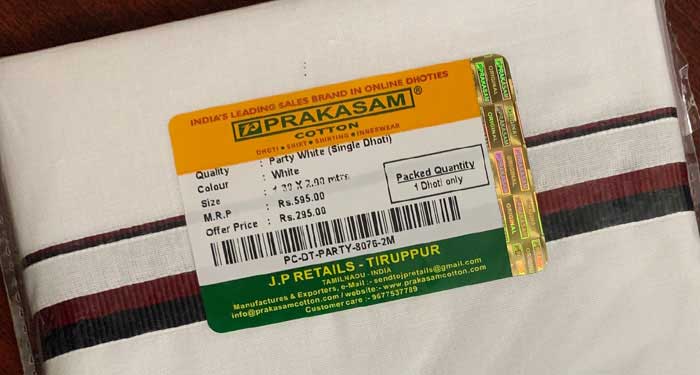

Holographic Hot Stamping Foils for Textile Labels

Holographic hot stamping foils bring a touch of elegance and innovation to textile labels. Through a heat transfer process, these foils are applied to fabric labels, creating stunning, multi-dimensional effects that draw attention. The intricate designs not only enhance the visual appeal but also offer added protection against counterfeiting. Ideal for high-end fashion and apparel brands, holographic hot stamping foils elevate textile labels by combining sophisticated aesthetics with robust security features.

Holographic Hot Stamping Foils for FMCG Labels

Holographic hot stamping foils offer a stunning way to enhance food labels with vibrant, eye-catching designs. These foils not only elevate the visual appeal of packaging but also provide a layer of security against tampering or counterfeiting. Ideal for branding, they add a premium look to labels, making products stand out on crowded shelves. Their combination of aesthetics and functionality makes them an excellent choice for FMCG labels in today’s competitive market.

Holographic Hot Stamping Foils for Coupons

Holographic hot stamping foils add a dynamic and attractive element to coupons, making them more eye-catching and engaging. Applied through a heat transfer process, these foils create vibrant, multi-dimensional effects that grab attention and enhance the visual appeal of promotional materials. Beyond aesthetics, the intricate designs provide an additional layer of security, helping to prevent coupon fraud and ensuring authenticity. Ideal for various marketing campaigns, holographic hot stamping foils make coupons not only visually appealing but also secure and trustworthy.

Holographic Hot Stamping Foils for Certificates

Holographic hot stamping foils are a precise and reliable solution for enhancing certificates with security and elegance. These foils ensure accurate alignment of holographic designs, creating a seamless and professional look on the document. Their vibrant, multi-dimensional effects not only elevate the certificate’s appearance but also add a layer of anti-counterfeiting protection, safeguarding its authenticity. Perfect for academic, corporate, or achievement certificates, Eye mark registration guarantees precise quality, making it a preferred choice for premium and secure certification needs.

Holographic Hot Stamping Foil Transfer Process

Holographic hot stamping foils are specialized materials used to create decorative, reflective, and security-enhanced designs on various surfaces, such as paper, plastic, or metal. These foils contain holographic patterns that diffract light, creating a shimmering, three-dimensional effect. To transfer these holographic stamping foils onto a substrate, two primary types of machines are commonly used: flatbed hot stamping machines and rotary hot stamping machines. Each machine has its own advantages and is suited for specific applications. Here's an elaboration on both:

Holographic Hot Stamping Foils Transfer Process - Flatbed Machine

Flatbed hot stamping machines operate in a stamping motion, where the foil is pressed onto the substrate using a heated die. The process involves the following steps:

Process: The substrate is placed on a flat surface (the “flatbed”), and the holographic foil is positioned between the substrate and the heated die. The die is then pressed down with controlled pressure and heat, transferring the foil onto the substrate.

Applications: Flatbed machines are ideal for small to medium production runs, thick or rigid materials, and detailed designs. They are commonly used for packaging, labels, book covers, and security documents.

Advantages:

High precision and detail due to the flat pressing motion.

Suitable for uneven or irregularly shaped substrates.

Easy to set up and adjust for different designs.Limitations :

Slower production speed compared to rotary machines.

Not ideal for high-volume production.

Holographic Hot Stamping Foils Transfer Process - Rotary Machine

Rotary hot stamping machines use a rotary motion to transfer the foil onto the substrate. The process involves a rotating cylinder and a continuous feed of the substrate and foil.

Process: The substrate and foil pass between a heated cylinder (with the engraved design) and a counter-pressure roller. As the cylinder rotates, the foil is transferred onto the substrate in a continuous motion.

Applications: Rotary machines are ideal for high-speed, high-volume production, such as roll-to-roll printing, flexible packaging, labels, and thin films.

Advantages:

Faster production speeds, making it cost-effective for large runs.

Consistent quality and even pressure distribution.

Suitable for thin and flexible materials.Limitations :

Less suitable for thick or rigid materials.

Higher initial setup cost and complexity.

Both flatbed and rotary hot stamping machines can effectively transfer holographic hot stamping foils, but the choice depends on the specific requirements of the project, such as production volume, material type, and design complexity. Flatbed machines excel in precision and versatility for smaller runs, while rotary machines dominate in speed and efficiency for large-scale production.

Advantages of Holographic Hot Stamping Foils

For companies and organizations trying to safeguard their products and reputation, hologram hot stamping foil has several advantages. The following are some of the primary advantages of Holographic hot stamping foil.

COUNTERFEIT MEASURES

An efficient security measure that can help stop counterfeiting and shield products from being tampered with or reproduced is hologram hot stamping foil. The foil’s ability to produce a 3D holographic images makes it a valuable tool in the battle against counterfeit products.

EYE APPEAL

Hologram hot stamping foil has security advantages, but it may also provide a product or document a distinctive and eye-catching touch. The foil’s creation of a 3D holographic image can draw attention to the products and improve its overall look.

PERSONALIZATION

These holograms may be personalized with distinctive patterns, styles, and branding components, increasing their difficulty to copy and boosting the marketing and branding of the products.

SAFEGUARDING BRANDS

The reputation, influence, and income of a brand can all be significantly impacted by counterfeiting and product tampering. Brands may safeguard their reputation and merchandise from these dangers by employing holographic hot stamping foil.

GENUINENESS

Brands can use these kinds of holograms to demonstrate the legitimacy of their goods. Brands may provide customers an obvious and visible indicator that a product is authentic by adding a holographic stamped on to it.

RESILIENCY

These holographic hot stamping foils are strong and resistant to many kinds of weather, therefore the security features will hold true for the duration of the goods.

FAQ's

What are holographic stamping foils used for?

Holographic stamping foils are specialty films used in the hot stamping process to apply dazzling, metallic, and three-dimensional holographic effects to various surfaces. They are primarily used for brand enhancement, security, and aesthetic appeal on products like packaging, labels, publications, certificates, and promotional items.

What materials can I use Holoseal foils on?

Our foils are engineered to work on a wide range of materials, including:

Papers & Cards: Coated, uncoated, and laminated stocks.

Plastics: PVC, PET, Polypropylene, and ABS.

Metallized Surfaces: For creating striking layered effects.

Varnished Surfaces: Certain UV and aqueous coatings. (We recommend requesting a sample roll to test compatibility with your specific substrate.)

Are your holographic foils customizable?

Absolutely! We specialize in customization. You can create a unique brand identity with:

Custom Holographic Patterns: Design an exclusive pattern or motif.

Branded Security Features: Incorporate microtext, QR codes, or company logos for anti-counterfeiting.

Master Origination: We can produce a brand new master shim based on your artwork.

Standard Patterns: We also offer a wide selection of stock patterns for immediate use, like with text “original” “genuine” etc..

Do these foils offer security features?

Yes, many of our holographic foils are ideal for security applications. They can be customized with features such as kinetic movement effects and microtext that are extremely difficult to replicate, making them perfect for protecting brands, documents, and high-value products.

What is the minimum order quantity (MOQ) for custom foils?

We understand the need for flexibility. For custom holographic foil orders, our standard MOQ is 150 Sq. Meter per design. However, we encourage you to contact our sales team to discuss your specific project needs, as we may be able to accommodate smaller quantities for testing or specific applications.

How do I determine the right foil for my application?

The best foil depends on your substrate (material), the stamping machine, and the desired effect. Our technical experts are here to help you choose the perfect foil. Please contact us with details about your application, and we will provide a specific recommendation and complimentary samples.

Can I get samples before placing a bulk order?

Yes, we highly encourage it! We offer sample rolls of our standard patterns so you can test the foil on your production line and ensure it meets your expectations for adhesion, finish, and visual impact. Please reach out to our team to request samples.

What are the available foil sizes and specifications?

Our foils are available in standard widths and lengths to fit most hot stamping machines. Common specifications include:

Widths: Ranging from 8mm to 150mm.

Lengths: Typically 300 meters per roll (on 1″ cores).

Packaging: Shipped on pallets for protection.

Detailed technical data sheets are available upon request.

How should I store the holographic foils?

To preserve their quality and ensure optimal performance, store the foil rolls in a cool, dry place away from direct sunlight and moisture. Ideal storage conditions are at room temperature (20-25°C) with low humidity. Keep the rolls in their original packaging until ready for use.

I'm new to hot stamping. Can you provide technical support?

Certainly! Our team doesn’t just sell foils; we provide solutions. We offer comprehensive technical support, including guidance on machine settings (temperature, pressure, dwell time) and best practices for achieving a perfect stamp every time.

How do I request a quote?

Requesting a quote is easy. Simply visit our contact us page, fill out the form with your details about substrate type, desired pattern, and estimated quantity, and our sales team will get back to you with a competitive quotation promptly.

What is the difference between a standard pattern and a custom origination?

Standard Patterns: These are pre-made, “off-the-shelf” holographic generic texts (like “original”, “genuine” etc.). They are cost-effective and available for immediate shipment with lower MOQs.

Custom Origination: This involves creating a brand new, unique master shim exclusively for your brand. This process has a higher initial cost and MOQ but results in an unforgeable, proprietary security or branding element.

What is the typical lead time for custom origination and foil production?

The lead time can vary based on the complexity of the design.

Custom Origination (Master Development): Typically takes 1-2 weeks.

Foil Manufacturing: After the shim is approved, production for a custom foil order usually takes 2-3 weeks.

Lead times for standard pattern foils are significantly shorter. We always provide an estimated timeline upon order confirmation.

What hot stamping machines and presses are your foils compatible with?

Our foils are compatible with all major brands of hot stamping machinery, including:

Flatbed Presses: Ideal for labels, packaging, and smaller, flat surfaces.

Rotary/Roll-on Presses: Used for high-speed, continuous applications like rolling on film or paper webs.

Vertical Presses: Often used for specific applications like cosmetics or electronics.

Our foils are engineered to perform consistently across different machine types.

What are the key factors for achieving a perfect stamp?

A perfect stamp depends on three critical parameters:

Temperature: Too low and the foil won’t transfer fully; too high and it can scorch the substrate or the foil.

Pressure: Insufficient pressure leads to a patchy transfer; too much can cause die bounce or crush the substrate.

Dwell Time: The duration the die is in contact with the substrate. This must be calibrated for the specific material and machine speed.

We provide recommended starting parameters with all our foil shipments.

My foil is not adhering properly. What could be the cause?

Poor adhesion can be caused by several factors:

Incorrect Machine Settings: Temperature, pressure, or dwell time is off.

Substrate Issues: The surface might be contaminated with silicone, dust, or oils, or the varnish/coating may be incompatible.

Die Condition: A worn-out or damaged die won’t apply heat and pressure evenly.

Our technical support team can help you troubleshoot adhesion issues.

Do you offer environmentally friendly or recyclable foil options?

We are committed to sustainability. We offer foils that are compatible with standard paper recycling streams. The amount of foil used is minimal, and during the recycling process, it is typically separated from the paper pulp.

What is your policy on defective materials?

We stand by the quality of our products. If you receive a roll that is defective (e.g., core issues, slitting errors, or consistent transfer problems not related to machine setup), please notify us immediately. We will arrange for an inspection and, if confirmed, provide a replacement.

Do you provide art file guidelines for custom origination?

Yes. For the best results in creating your custom holographic master, we require artwork in a specific vector-based format (like CorelDraw). We will provide you with a detailed Artwork Guideline document upon inquiry to ensure a smooth and accurate origination process.

Holographic Hot Foil Stamping to Deter Counterfeiting

Enhance security and brand value with Holoseal’s custom holographic hot stamping foils. Ideal for premium packaging and anti-counterfeiting measures, our foils are durable, versatile, and designed for high-volume application. Inquire about custom solutions.

Do you have any doubts or queries about Holographic Hot Stamping Foils ?

Call/ WhatsApp : +91-8928181178 or Email : sales@holoseal.in