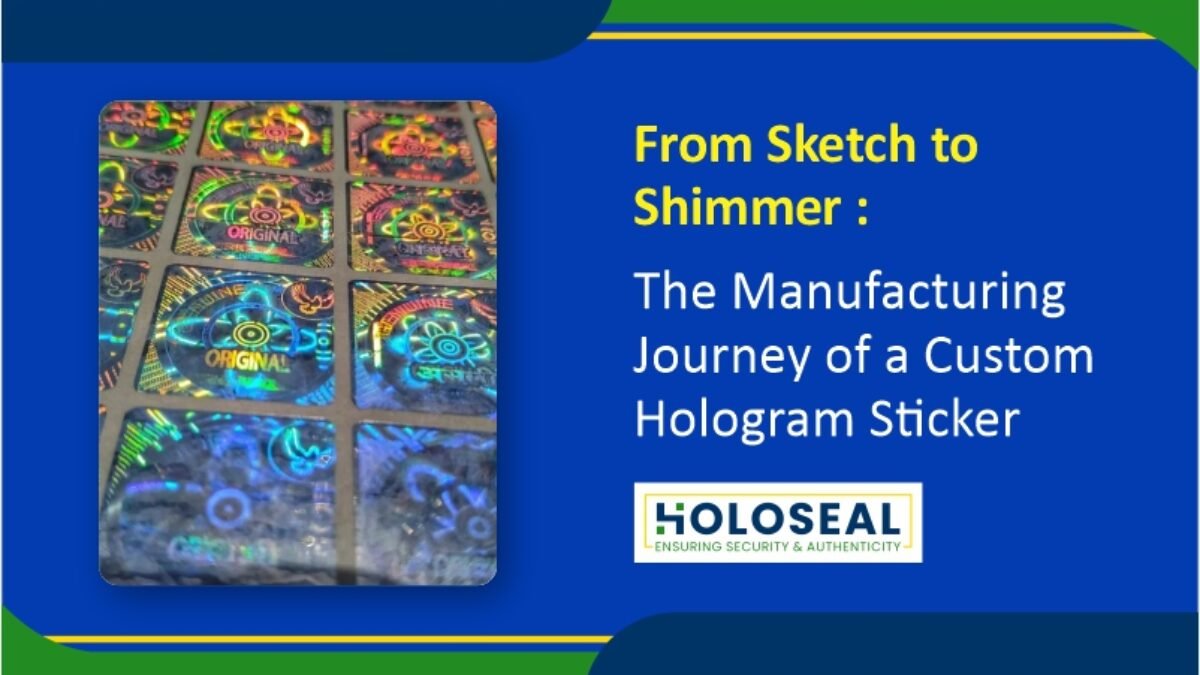

The final product—a custom hologram sticker gleaming on your packaging—is a moment of security and brand assurance. But its journey from a conceptual sketch to that definitive shimmer is a marvel of precision engineering and multi-stage craftsmanship. At Holoseal, this journey is a meticulously controlled symphony of art, science, and technology. Let’s walk through the transformative stages that turn a brand’s idea into an unforgeable physical reality.

Phase 1: The Genesis – Strategic Design & Digital Blueprinting

It begins not in a factory, but in a collaborative dialogue. Our designers and security experts work with you to translate your brand identity and security needs into a visual concept. This stage defines the hologram’s personality: Will it feature a kinetic animation of your logo? Incorporate hidden microtext? Integrate with a tamper-evident void layer?

Once the concept is approved, it enters the digital forge. Using specialized software, artists and optical engineers convert the design into a mathematical vector file. This isn’t a standard image; it’s a data-rich blueprint specifying the exact angles, depths, and spatial frequencies of the diffraction gratings that will later bend light. This file is the digital DNA of your hologram.

Phase 2: The Heart – Master Origination via Electron-Beam Lithography

This is where uniqueness is born. The digital file is transferred to a master substrate—often a glass plate coated with an ultra-thin layer of photoresist. Inside a vacuum chamber, a focused beam of electrons (electron-beam lithography) scans across this plate, writing the nano-scale pattern with astonishing precision. This process, which can take many hours, creates the original master shim. This master is the singular, most valuable artifact in the chain—the negative from which all copies will spring. It is stored under high security, as it contains the irreplicable optical signature of your brand.

Phase 3: The Replication – Electroforming & Shim Production

To mass-produce the hologram, we need durable tools. The master shim undergoes an electroforming process. It is placed in an electrolytic bath where nickel ions are deposited onto its surface, building up a thick, robust metal shell that captures every nanometric detail of the original. This nickel shell is separated, becoming a father shim. From this, multiple mother and production shims can be generated. These final nickel shims are the workhorses—cylindrical rollers or flat plates—that will be mounted onto the embossing machinery.

Phase 4: The Embodiment – Embossing & Metallization

Here, the pattern becomes physical. A roll of clear, virgin polyester (PET) film is fed through a high-pressure embossing machine. The nickel production shim presses (embosses) the intricate 3D pattern onto the film with heat and pressure. What emerges is a transparent film bearing a microscopic, textured landscape.

This embossed film then enters a vacuum metallizer. In a chamber under high vacuum, a source material (typically aluminum) is vaporized, and the metallic vapor condenses evenly onto the embossed film. This metallic layer acts as a mirror, reflecting light and allowing the diffractive pattern to produce its characteristic rainbow color and dynamic imagery. For selective effects, a demetallization process can be applied to remove metal from specific areas, creating transparent windows or logos.

Phase 5: The Fortification – Lamination, Coating & Converting

The holographic film is now a security medium, but not yet a finished sticker. To achieve tamper-evidence, it is often laminated to a destructible void film—a layer that will fracture and reveal a “VOID” message if removed. Next, a high-performance, permanent adhesive is coated onto the back. The material may also receive additional secure prints, such as UV-reactive inks, serialized batch numbers, or scrambled QR codes.

Finally, the multi-layered roll is die-cut into its final shape—be it circles, ovals, or custom contours—and rewound into finished sticker rolls, ready for application.

Phase 6: The Vigil – Rigorous Quality Assurance

No sticker leaves our facility without passing stringent checks. We verify optical clarity, diffraction efficiency, adhesive strength, and the flawless function of all covert features (like UV response and microtext legibility). We ensure every batch meets the exact specifications born in the first phase, guaranteeing consistent performance and security.

The Holoseal Promise: A Journey of Trust

This intricate journey from sketch to shimmer is why a Holoseal Hologram sticker is not a commodity but a custom-engineered security device. It embodies a chain of custody over light itself, resulting in a brand guardian that is as technically profound as it is visually striking. It’s a testament to the fact that true security is never just applied—it is meticulously built, layer by layer.

Witness the precision behind the protection. Partner with Holoseal to begin your product’s journey to secure brilliance at www.holoseal.in.